tube bundle re-tubing equipment

In order to facilitate the tube bundle re-tubing, electro mohareke Parsian Company has produced and localized various types of tube bundle re-tubing devices.

Replacing this equipment reduces potential hazards, increases safety at work, and reduces time and cost.

Traditional method of tube bundle re-tubing

Time is of the essence in major repairs. Every effort is made by the parent industry to reduce time. Devices and tools are used to facilitate repairs and reduce equipment damage.

In the traditional method, using a crane, the whole tube bundle is opened with a shell and transferred to the ground. Then, by fixing the shell, they try to hit and pull the tube bundle out of the shell.

Power is applied by the loader, which is very time consuming and dangerous and causes serious damage to the tube bundle.

Free technical advice

Contact us for technical advice and more information

Types of tube bundle re-tubing equipment

This machine extracts tube bundle at any height without the slightest damage, according to HSE instructions at high speed. The speed of pulling out and inserting the tube bundle in the tube bundle extractor machine is one meter per minute. Hydraulic force prevents impact and damage to the tube bundle.

After pulling out the tube bundle, belts and cranes are used to move and transport the tube bundle. This method causes bending and damage to the tubes due to the concentration of the load at two points. The wide-loaded lift bundle tube can be easily carried with even a forklift. In the traditional method, cranes are used to rotate the tube bundle and repair and wash the tube bundle. This method is very dangerous.

The roller bundle tube machine rotates the tube bundle with hydraulic force and very safely. This period is done to facilitate the work of washing the tube bundle. grippul machine re-tubing After cutting the tube from the back of the tube, the tubes inside the tube are removed. In the traditional method, this is done using a drill, a mandrel and a blow. In the Grippul device manufactured by electro mohareke Parsian Company, the tube sheets can be removed without the need for impact or the slightest damage.

The dramatic advantage of using a grippul machine

In the traditional method, it takes about 15 minutes to remove the herb tube with a drill and pin. But the Grippul machine extracts 4 to 6 tubes per minute, which significantly reduces repair time.

Electro mohareke Parsian Company is ready to provide all services and manufacture various types of tube bundle re-tubing devices.

tube bundle re-tubing equipment

tube bundle re-tubing equipment

In order to facilitate the tube bundle re-tubing, electro mohareke Parsian Company has produced and localized various types of tube bundle re-tubing devices.

Replacing this equipment reduces potential hazards, increases safety at work, and reduces time and cost.

Traditional method of tube bundle re-tubing

Time is of the essence in major repairs. Every effort is made by the parent industry to reduce time. Devices and tools are used to facilitate repairs and reduce equipment damage.

In the traditional method, using a crane, the whole tube bundle is opened with a shell and transferred to the ground. Then, by fixing the shell, they try to hit and pull the tube bundle out of the shell.

Power is applied by the loader, which is very time consuming and dangerous and causes serious damage to the tube bundle.

Types of tube bundle re-tubing equipment

tube bundle extractor machine

This machine extracts tube bundle at any height without the slightest damage, according to HSE instructions at high speed. The speed of pulling out and inserting the tube bundle in the tube bundle extractor machine is one meter per minute. Hydraulic force prevents impact and damage to the tube bundle.

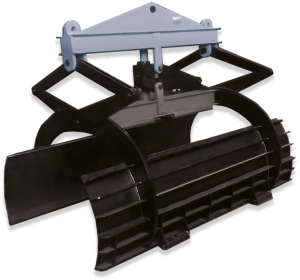

tube bundle lifter machine

After pulling out the tube bundle, belts and cranes are used to move and transport the tube bundle. This method causes bending and damage to the tubes due to the concentration of the load at two points. The wide-loaded lift bundle tube can be easily carried with even a forklift. In the traditional method, cranes are used to rotate the tube bundle and repair and wash the tube bundle. This method is very dangerous.

tube bundle roller machine

The roller bundle tube machine rotates the tube bundle with hydraulic force and very safely. This period is done to facilitate the work of washing the tube bundle. grippul machine re-tubing After cutting the tube from the back of the tube, the tubes inside the tube are removed. In the traditional method, this is done using a drill, a mandrel and a blow. In the Grippul device manufactured by electro mohareke Parsian Company, the tube sheets can be removed without the need for impact or the slightest damage.

The dramatic advantage of using a grippul machine

In the traditional method, it takes about 15 minutes to remove the herb tube with a drill and pin. But the Grippul machine extracts 4 to 6 tubes per minute, which significantly reduces repair time.

Electro mohareke Parsian Company is ready to provide all services and manufacture various types of tube bundle re-tubing devices.

Free technical advice

Contact us for technical advice and more information